What's a Motional Digital Twin?

How the third generation of Digital Twin technology is transforming the way infrastructure operators understand and optimize the movement of people and vehicles.

Every day, millions of people move through airports, train stations, stadiums, and other large-scale infrastructures.

They queue, they browse, they rush to connections, they linger in retail zones. Vehicles circle parking structures, navigate curbsides, and cross busy intersections.

This lack of visibility into physical flows is more than an inconvenience — it is a fundamental operational blind spot. Without precise, real-time understanding of how people and vehicles move through a space, operators cannot identify bottlenecks before they escalate, resolve inefficiencies that erode service quality, or mitigate safety risks hidden in everyday patterns.

It is, paradoxically, both their most significant data gap and their most powerful lever for improvement.

It represents the emerging third generation of Digital Twin technology, purpose-built not for static structures or asset maintenance, but for the dynamic reality of day-to-day operations.

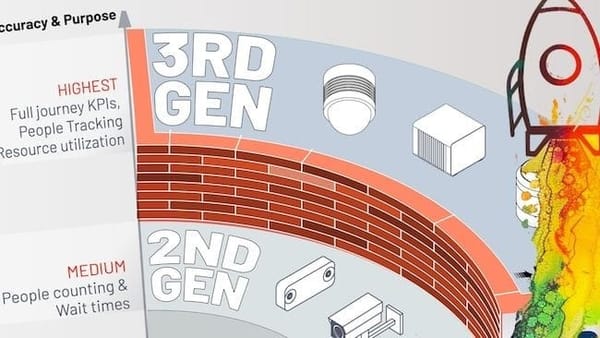

The Evolution of Digital Twins — From Static to Dynamic

The concept of a Digital Twin is not new.

What has changed dramatically is what Digital Twins are capable of representing — and the operational value they can deliver.

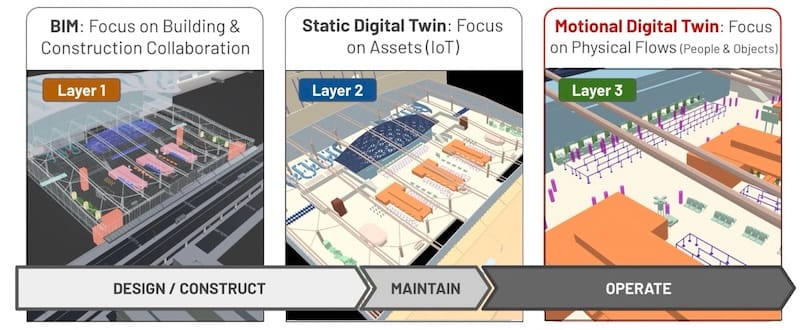

This evolution has unfolded across three distinct generations, each building on the last.

- The first generation, Building Information Modeling (BIM), emerged as a powerful tool for the design and construction phases of infrastructure projects. It is invaluable for architects, engineers, and construction managers. But once a building is operational, BIM remains essentially static. It describes what a space is, not what is happening inside it.

- The second generation, Real-Time Digital Twins, extended this foundation by integrating IoT sensor data to monitor the condition and performance of physical assets in real time. Temperature sensors, vibration monitors, energy meters, and similar devices feed continuous data into the digital model, enabling predictive maintenance, energy optimization, and asset lifecycle management.

- The third generation — Motional Digital Twins — adds the critical dimension that the previous two generations lacked: the continuous digitization of movement. Rather than modeling static structures or monitoring fixed assets, a Motional Digital Twin captures how every individual person and vehicle moves, behaves, and interacts within a physical environment, in real time, and transforms that data into actionable intelligence.

What Makes a Motional Digital Twin Different?

A Motional Digital Twin is defined by a set of core principles that distinguish it from all previous generations of Digital Twin technology. Understanding these principles is essential to grasping why MDTs deliver a fundamentally different kind of operational intelligence.

Movement-driven

An MDT examines reality from the perspective of motion and behavioral data, rather than static structural information or simple sensor readings.

Movement is not a secondary feature layered onto a building model — it is the foundation on which every insight is built.

Real-time and continuous

Data acquisition and processing operate at frequencies that match the speed of physical movement.

This real-time capability is essential because movement, by its nature, is ephemeral. A bottleneck that forms and dissipates in seven minutes is invisible to any system that operates on longer cycles.

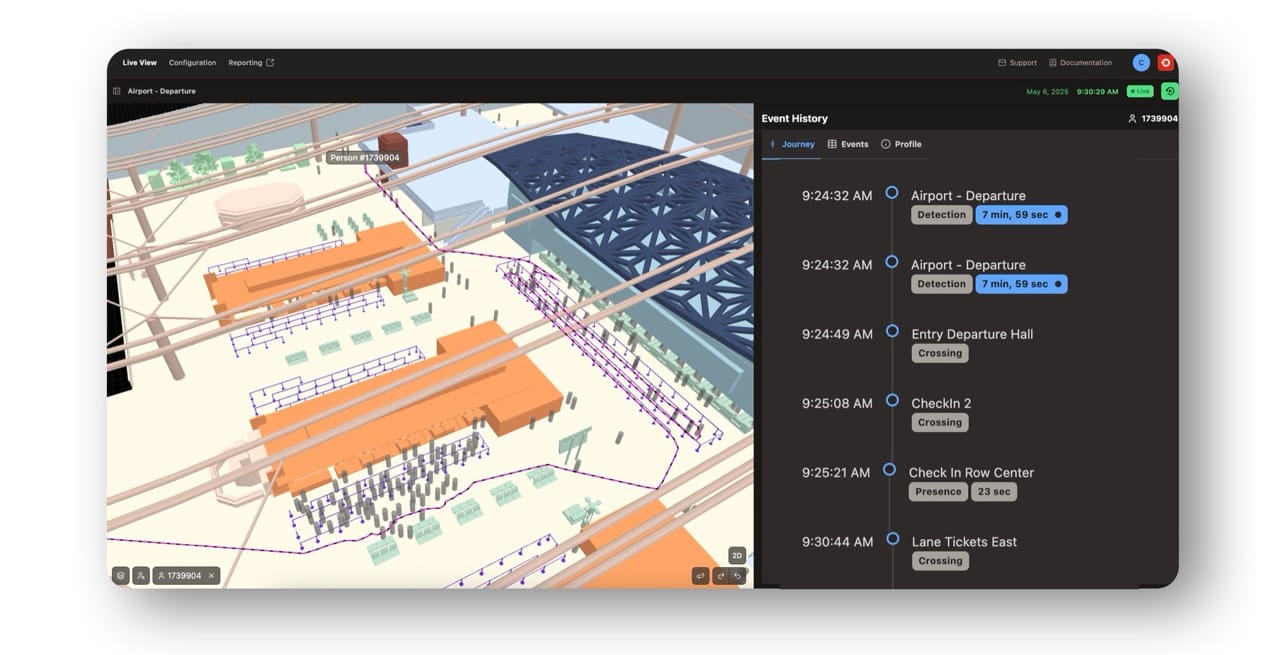

Individual-level tracking

Each person or object within the environment receives a unique, anonymous identifier that is maintained throughout their entire presence in the space.

This is a critical distinction from legacy approaches that rely on aggregated counts or statistical averages.

Spatial interactions

An MDT captures not only where individuals are, but how they behave and interact, with each other, with physical assets, and with their surroundings.

Centimeter-level precision

Spatial accuracy must be consistent with the behaviors and interactions that need to be captured.

Sub-20 centimeter precision is required to understand person-to-person interactions in crowded environments, while sub-1 meter accuracy may suffice for parking monitoring. The system adapts its precision to the context.

Privacy-preserving by design

No images are captured or stored. Every person and vehicle is represented by an anonymized symbol.

These principles are not optional features. They are the defining characteristics that make a Motional Digital Twin capable of delivering the operational intelligence that previous generations of Digital Twins simply cannot provide.

How It Works: The Three Processing Layers

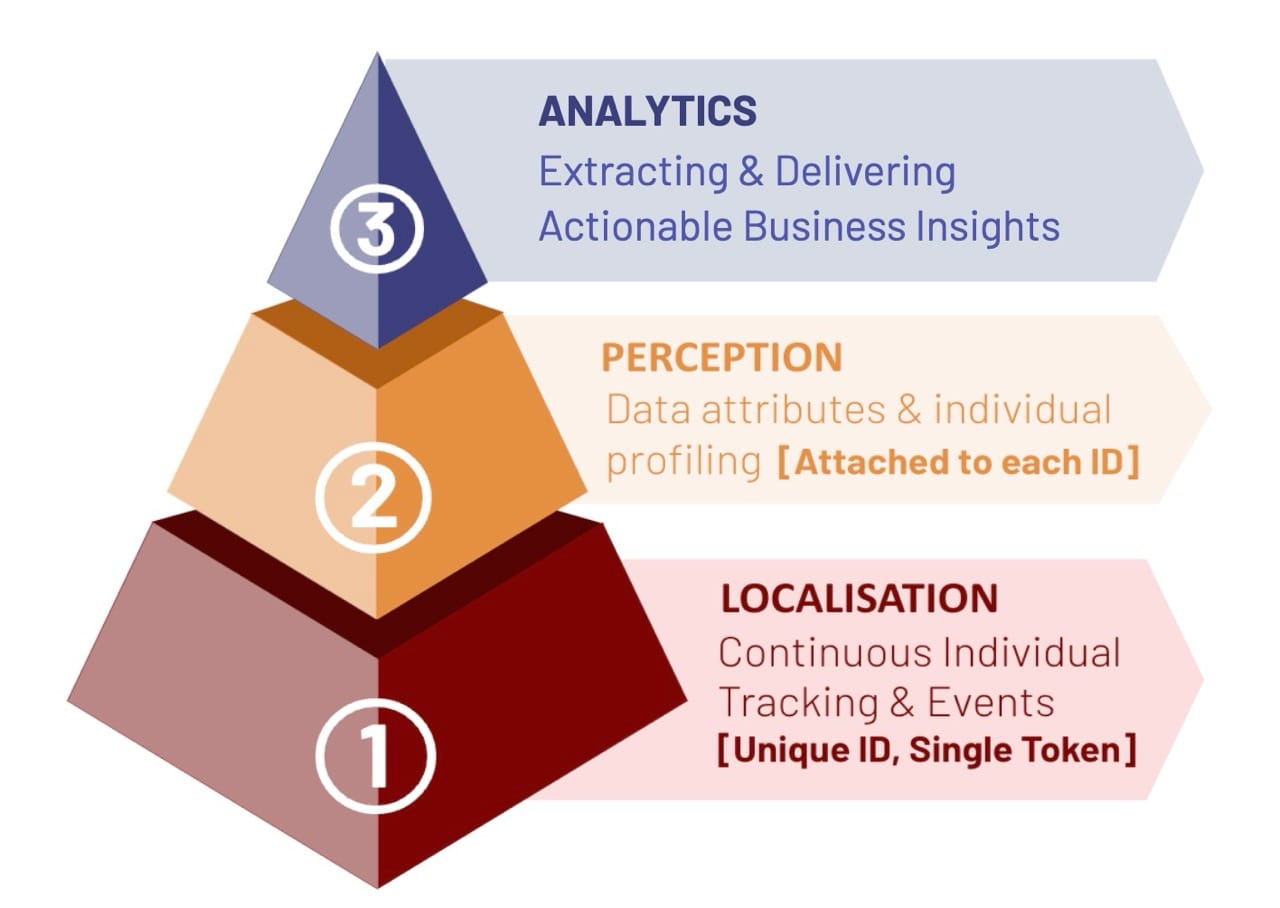

Beneath the real-time 3D visualization and the dashboards that operators interact with, a Motional Digital Twin relies on three fundamental processing layers.

Each builds on the one before it, and together they transform raw sensor data into the actionable insights that drive operational decisions.

Localization: Continuous Individual Tracking

The first and most critical layer is the ability to precisely position every person or object across an entire premises and maintain a unique, consistent anonymous identifier for each one throughout their journey. This is the cornerstone on which everything else depends.

It also establishes the consistent spatial and temporal reference frame required for all downstream analysis. Without reliable localization, perception and analytics have no foundation.

This is made possible by LiDAR technology's ability to natively and accurately perceive in three dimensions, combined with advanced Physical AI software that can maintain tracking even in complex, densely crowded environments where individuals frequently occlude one another.

Perception: Situational Awareness

The second layer builds on localization by adding understanding.

Perception capabilities enable the system to recognize what objects are and what they are doing: classifying people, staff, vehicles, and vulnerable road users; detecting behaviors such as running, loitering, or queueing; and associating external data attributes with each tracked identifier.

For example, automatic staff detection allows the system to exclude employees from passenger wait-time calculations while simultaneously enabling workforce optimization insights.

Linking a passenger's anonymous identifier to flight information enables an entirely new level of business intelligence.

Analytics: Actionable Insights

The third layer transforms the rich data produced by localization and perception into meaningful business intelligence. This is where raw movement becomes operational value.

A Motional Digital Twin must deliver insights across three time horizons.

- In the present, it provides a live 3D map of the environment, real-time KPI dashboards, and immediate alerts through SMS, email, or integrated alerting systems.

- Into the past, it offers full journey replay, historical KPI trends, and the ability to revisit any moment in the 3D map — effectively enabling operators to "time travel" to understand what happened and why.

- And into the future, it generates anticipated KPIs based on historical patterns, per-individual journey predictions, and early warnings of emerging bottlenecks, congestion, or safety risks.

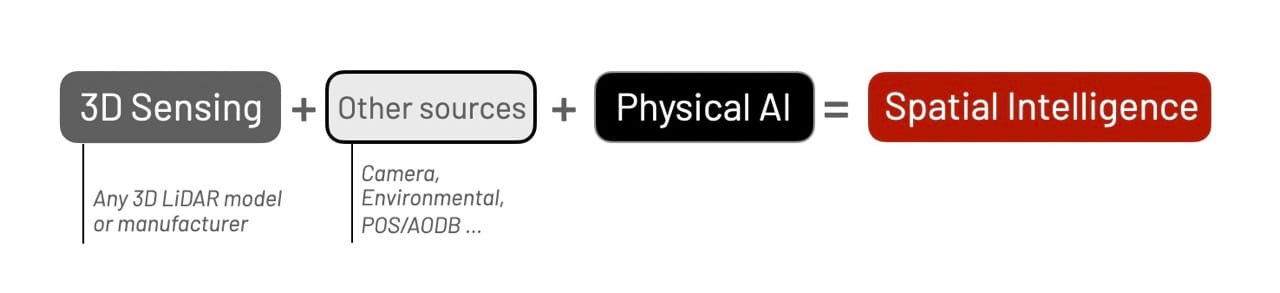

The Technology Foundation: Physical AI and LiDAR

Two converging technological advances make Motional Digital Twins possible: Physical AI and 3D LiDAR sensing.

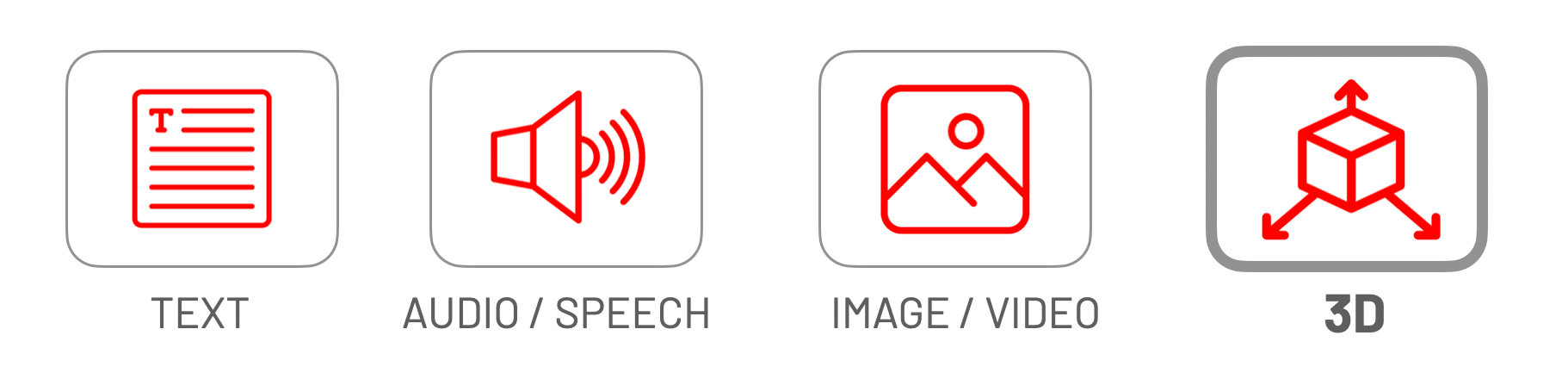

Physical AI represents a set of artificial intelligence techniques designed to understand and analyze movement and behavior in three-dimensional space.

What makes Physical AI distinctive is that it handles the fourth major data modality in artificial intelligence — alongside text, audio, and image/video, the 3D modality represents the physical world as it actually exists in space and time.

Spatial Intelligence is the term for the actionable insights generated by Physical AI as it processes data from 3D native sensors and other external sources within a consistent 3D reference system.

LiDAR (Light Detection and Ranging) is the key enabling sensor technology.

By emitting pulses of invisible laser light and timing reflections millions of times per second, LiDAR builds highly accurate 3D representations of an environment.

Compared to legacy technologies such as cameras, radar, or simple beam counters, LiDAR brings a unique combination of advantages: native 3D spatial data providing distance, size, volume, and speed; detection ranges up to hundreds of meters enabling wide-area coverage with fewer units; centimeter-level accuracy maintained regardless of distance; reliable operation in complete darkness and challenging lighting conditions; and — critically — privacy by design, since no facial or image data is ever captured.

Originally developed by NASA in the 1970s and matured through massive investment in the automotive sector, LiDAR hardware has now reached a point where performance and cost make it viable for infrastructure applications at scale.

Why now?

The maturity of native 3D sensing technology, combined with the readiness of Physical AI software platforms capable of processing massive 3D data streams in real time, is what makes the third generation of Digital Twins achievable today.

Six drivers have converged to make this the right moment for Motional Digital Twins:

- Mature and affordable LiDAR sensors,

- Proven Physical AI platforms ready for scale deployment,

- Next-generation edge computing capable of real-time 3D data processing,

- Web-based 3D interfaces that run seamlessly in any browser,

- Rising public and regulatory resistance to image-based surveillance,

- and growing global adoption by leading operators across the Americas, Europe, the Middle East, and Asia.

Where MDTs Deliver Value

One of the most important characteristics of a Motional Digital Twin is its platform-based architecture.

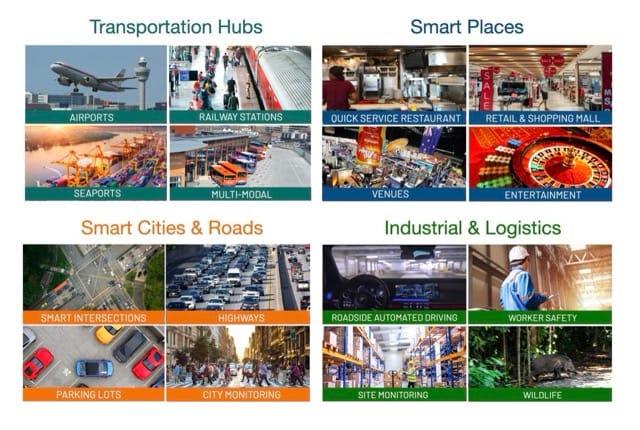

This horizontal applicability extends across industries. Motional Digital Twins are deployed today at scale in transportation hubs, tourism and cultural sites, retail environments, stadiums and large venues, road infrastructures, industrial plants, logistics hubs, and security-sensitive facilities.

In each case, the core value proposition is the same: transforming invisible movement patterns into actionable intelligence.

Conclusion

A Motional Digital Twin transforms what has historically been invisible, the continuous, complex movement of people and vehicles through physical spaces, into precise, actionable Spatial Intelligence.

This represents a fundamental advance beyond previous generations of Digital Twin technology. Where BIM modeled static structures and Real-Time Digital Twins monitored fixed assets, Motional Digital Twins capture the dynamic operational reality that matters most to infrastructure operators: how their spaces are actually being used, moment by moment, person by person.

The operational implications are profound.

- Bottlenecks can be identified and resolved before they escalate.

- Workforce allocation can be aligned with actual demand rather than estimates.

- Customer experiences can be improved through reduced wait times, seamless navigation, and personalized service.

- Safety risks can be detected and mitigated in real time.

- Revenue can be optimized through data-driven decisions about layout, staffing, and commercial operations.

They are rapidly becoming essential infrastructure, and the operators who adopt them early will secure a lasting operational edge.

For more details, you can download our comprehensive whitepaper: