Streamlining Warehouse Operations with LiDAR Inventory Management

Learn how 3D LiDAR solutions can impact the way warehouses manage their inventory for greater accuracy and efficiency

Operators can finally overcome the challenges imposed by imprecise, inefficient, and manual inventory management methods for industrial materials, such as total stations, theodolites or compass and level instruments.

With 3D LiDAR technology, it's now possible leverage pulsed light waves emanating from a laser to create precise 3D point cloud images. By combining this technology with equally sophisticated software, accurate and real-time calculations of material volumes can be done in real-time and extremely high accuracy.

Learn more t he future of volume management with Outsight’s 3D LiDAR-based measurement solutions in this article:

Keep reading to discover how 3D LiDAR solutions can help materials inventory companies, like coal industries for instance, and other businesses make real-time volumetric measurements for more efficient stock control.

Challenges in Traditional Production and Warehousing

When dealing with warehousing or logistics, keeping track of quantities and volumes of materials—whether inbound, outbound or stored in a facility—is a tremendous challenge. And yet it’s critical to run a smooth operation.

Every industrial site must contend with this complexity but, for inventory management, some materials are more difficult than others. For coal warehousing and production, for instance, volumes are usually measured manually, with a total station operated by a worker.

Some of the many challenges inherent in this method include low efficiency, substantial margins of error, difficulty in monitoring, and technical deficiency on the part of the operator.

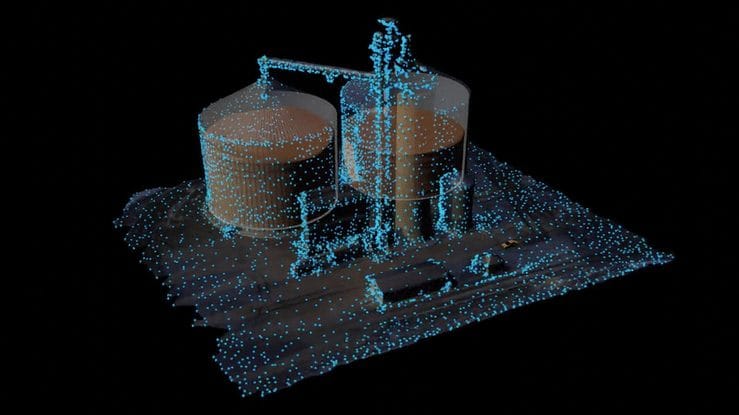

Point-cloud generated with Outsight's solution for measuring warehouse inventory volume

Obtaining precise measurements has been a long-standing problem in the materials industry. After all, what is the danger of being “off” on a measurement?

This shows the importance of accurate bulk material measurement, for both managing inventory and calculating consumption.

Large piles of materials are typically measured using a total station and real-time kinematic positioning (RTK) measurement. This type of procedure is highly inefficient because of the low data density that the spot measurement of the RTK provides. Besides, it also requires manual feature extraction, which is difficult if workers must climb the heap to do this, resulting in lower measurement accuracy.

What if there was a more clever way to measure a material volume that would provide accurate volume information, regularly updated in real-time throughout the production and distribution process?

The 3D LiDAR Solution for Efficient Inventory Management

Light Detection and Ranging (LiDAR) technology uses a laser pulse sent from a transmitter, which is reflected from target objects, and these reflected pulses are sent back to the system’s receiver, measuring the object’s distance. A LiDAR sensor sends millions of laser points each second for a complete picture of the target area. This instantaneous 3D data is called a point-cloud.

Learn the basics of how 3D LiDAR works with our previous article:

With the right software, it is possible to combine many point-clouds from different LiDARs to create a 3D map. This is important in order to have a precise inventory measurement in a large warehouse of thousands of squared-meters for instance.

Why are LiDAR Solutions so valuable compared to other camera solutions?

Neither cameras nor single-point lasers are able to collect the three-dimensional details of a material’s surface Ultrasound sensors have limitations as well, such as noise and reflection, signal absorption, a limited range, and high energy requirements. The equipment is expensive to install and it delivers faulty data.

Unlike other measuring methods that require ambient light, a LiDAR system can operate in low light as well as in darkness. It provides continuous, instant monitoring around the clock, 24/7.

3D LiDAR solutions are used to scan to calculate large piles of materials volumes in real-time

How 3D LiDAR Helps Mining Operations and Processing Plants

Using valuable insights from precise, ongoing 3D LiDAR solution measurements, mining companies can improve inventory accuracy, reduce the risk of shortages and overstocking, and ensure that shipments arrive in a timely manner.

In other words, precision volume measurements can be used to make better-informed decisions, maximize company efficiency, and reduce costs competitively.

Additionally, it can also be used to monitor the security of warehouse facilities by detecting an unexpected variation beyond a certain threshold in the volume.

Outsight's LiDAR Solution allows for precise and instantaneous stockpile monitoring that can be easily deployed in any warehouse facility and material type

How Else Can LiDAR Solutions be Applied in the industry?

3D LiDAR, through its enhanced point cloud density, delivers more highly detailed data for accurate volume measurements. But how else does this work in a practical sense? Here are two examples of practical applications using LiDAR solutions.

Load Volume Computation

One of the most interesting applications is the use of LiDAR Software to measure loads volume. In a recent Outsight client case, the load was composed by a large amount of fiber material delivered by truck and the volume measurement had to be done quickly and without human intervention.

Outsight's solution used two LiDARs plugged into a gantry to obtain information on the truck's load, such as its start and end point, width, height, and volume to generate the spatial data.

Then, the software fuses the point clouds from the two LiDARs, creates a 3D models of the moving object (in this case, a truck), segments the load of a vehicle, and calculates its volume with autonomy.

SLAM Algorithm on a moving truck generates a super-resolution scan

Security Control

The regular monitoring of goods using a 3D LiDAR solution has another benefit, in addition to providing volumetric measurements. It also allows companies to expand surveillance and prevent theft.

In another recent case, this time for a client that wanted to monitor company's inventory in real time, Outsight's Software was used to measure the volume and number of bags, as well as, generate and display an alarm in real time when volume/bag number variations occur.

Finally, the solution also allowed the user to view, at any time, the current volume and number of bags per cluster zone and the sum of the volumes and bags for the entire warehouse.

Conclusion

LiDAR Solutions, like Outsight's, empower businesses to get the most value from LiDAR systems as they provide the ability to choose the best sensors for a specific application, fuse multiple LiDAR devices (even from different manufacturers), and give the provide the full picture and information needed to boost efficiency and accuracy in volumetric measurements and beyond.

Learn more about our software by downloading our free white paper or schedule a meeting with a Product Specialist today. Discover how Outsight’s LiDAR solutions can help your business gain a competitive edge.