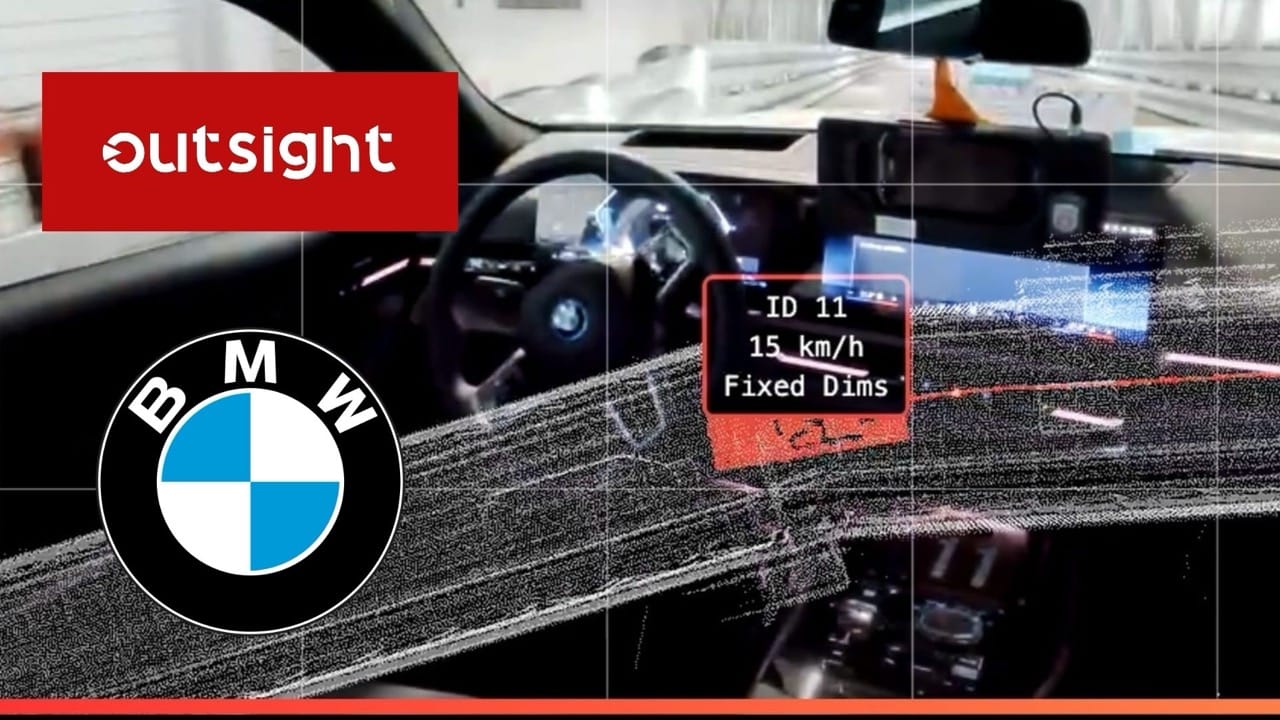

Outsight’s Physical AI Solution Powers Robotics Across BMW Factories

BMW has taken a significant step toward integrating autonomous capabilities within its production network, relying on Outsight’s innovative Physical AI solution

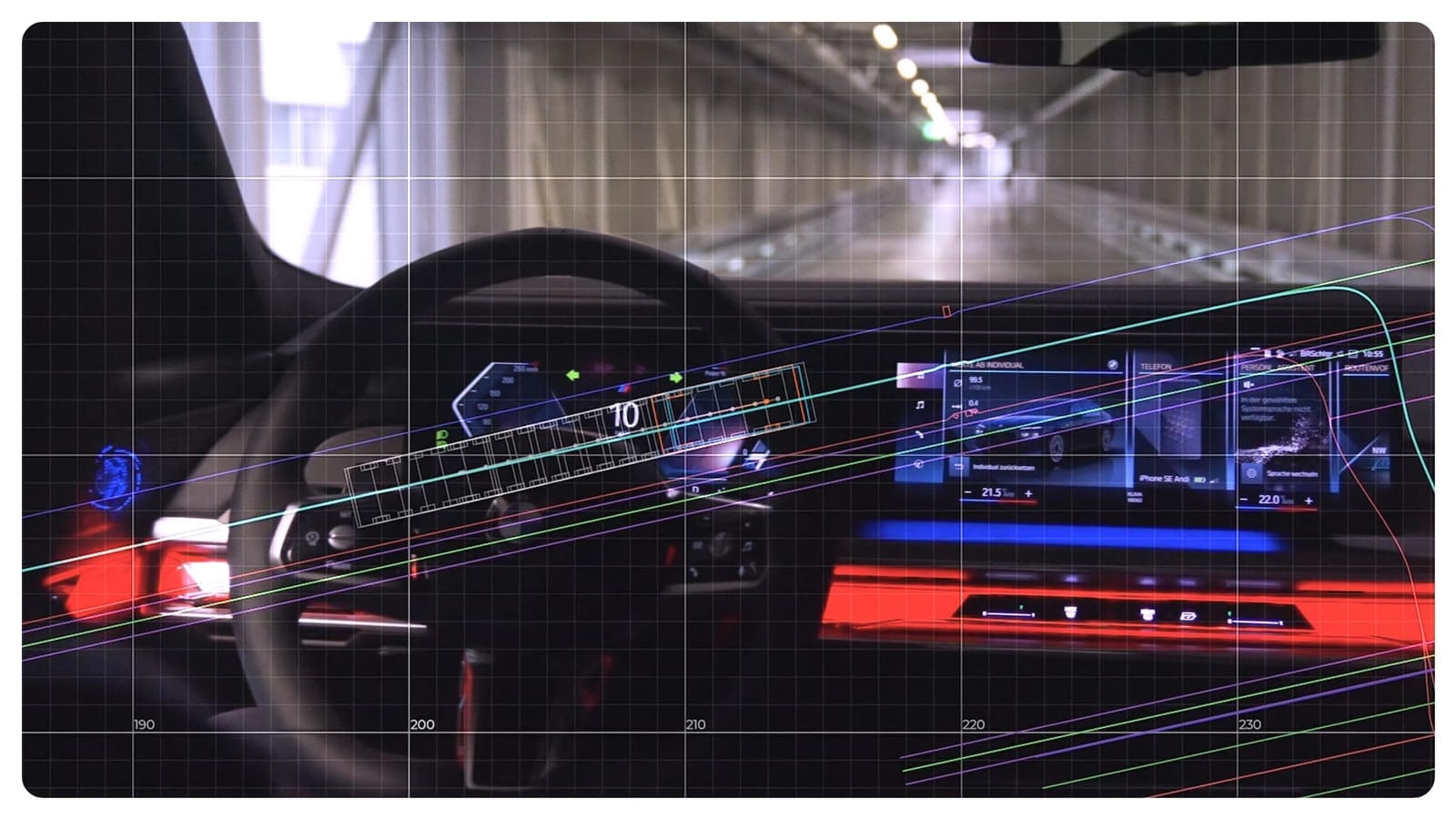

Physical AI leveraging LiDAR technology enables BMW's latest Series 5, Series 7, and MINI Countryman models to navigate autonomously to their finishing areas.

This showcases the potential of Spatial Intelligence not only in modern manufacturing but in any environment where mobile robots operate.

As part of its commitment to robotics, BMW has deployed Automated Driving In-Plant (AFW) at its Dingolfing plant, the largest in Europe.

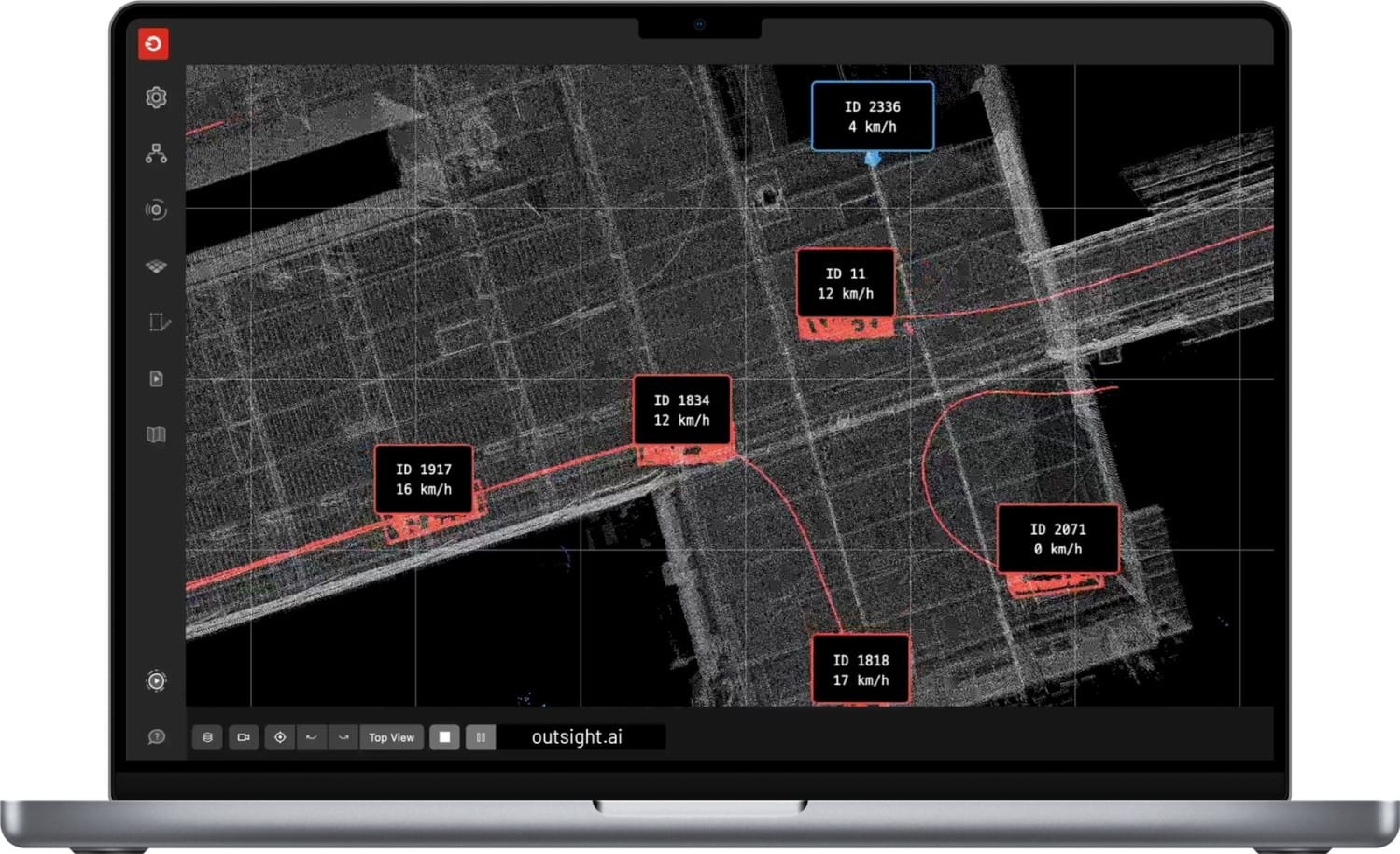

Using Outsight's Physical AI solution, and more specifically Beyond-Line-of-Sight Robotics, leveraging LiDAR sensors, new vehicles autonomously travel over one kilometer from assembly halls, through test courses, to finishing zones.

This breakthrough enhances both efficiency and safety, as Outsight's solution processes over 60 million LiDAR data points per second with under 100ms latency, to guide approximately 300 cars daily at Dingolfing.

The technology ensures precision and safety as vehicles autonomously navigate BMW facilities without human intervention.

Expanding the Impact of Robotics from the Infrastucture

With CE certification secured, BMW is rolling out across factories in Leipzig, Regensburg, Oxford, and the upcoming Debrecen facility in Hungary.

The implementation will contribute to BMW’s goal of logging millions of autonomous kilometers within its production network over the next decade.

Outsight Physical AI solution’s utility in dynamic environments extends beyond manufacturing, with proven applications in large venues such as airports and stadiums to enhance crowd management.

Outsight's solution, which is hardware-agnostic, processes up to 600 million data points per second and allows integration with sensors from multiple manufacturers.

This versatility enables swift hardware upgrades, ensuring future scalability.

According to Raul Bravo, President and co-founder at Outsight, “Our collaboration with BMW highlights the increasing maturity of Physical AI and LiDAR technology.Its application to real-world factory conditions demonstrate its ability to enhance industrial safety and efficiency, while underlining the importance of a comprehensive framework to realise the potential of mobile robotics.”

“Hesai is proud to partner with Outsight to deliver cutting-edge lidar technology for BMW’s system,” says Dr. David Li, CEO and Co-founder of Hesai Technology. “This state-of-the-art technology demonstrates the high level of precision and safety offered by our lidar and Outsight's perception software. We look forward to continuing our collaboration and bringing this technology to more factories around the world.”

This deployment marks the initial phase in a global rollout to multiple plants across Europe and North America.