LiDAR solutions for volume measurement

3D LiDAR solutions offer a solution for industries where traditional volume measurement methods are outdated by offering more accurate data

In today's fast-paced market, companies must maximize efficiency to stay ahead. One important way to reach this goal is to accurately measure and keep track of raw materials from planning to delivery.

Accurate volume measurement is a key part of this process because it allows for tracking inventory and measuring material stockpiles.

Various industries use 3D LiDAR solutions, such as agriculture, forestry, construction, and mining, where current technologies cannot achieve the desired precision and have high costs. These solutions can address the challenges faced by these industries and offer a way forward.

3D LiDAR technology provides more precise measurements at various stages, such as planning, production, and delivery, helping operations in these sectors make informed decisions, reduce costs, and enhance efficiency.

Traditional volume measurement

Traditional manual volume measurement methods, such as visual estimation, walking wheel instruments, and bucket/truckload counting, are outdated, inefficient, expensive, and often inaccurate.

Accurate volume measurement demands a complete scan of the material surface, considering surface-level variations. Other technologies, such as cameras or single-point lasers, cannot gather three-dimensional details of the entire surface, demanding more complex and costly installations.

Ultrasound sensors, on the other hand, suffer from issues like signal absorption, noise and reflection, limited range, and high energy needs, resulting in faulty data and expensive installations.

A new era for volume measurement

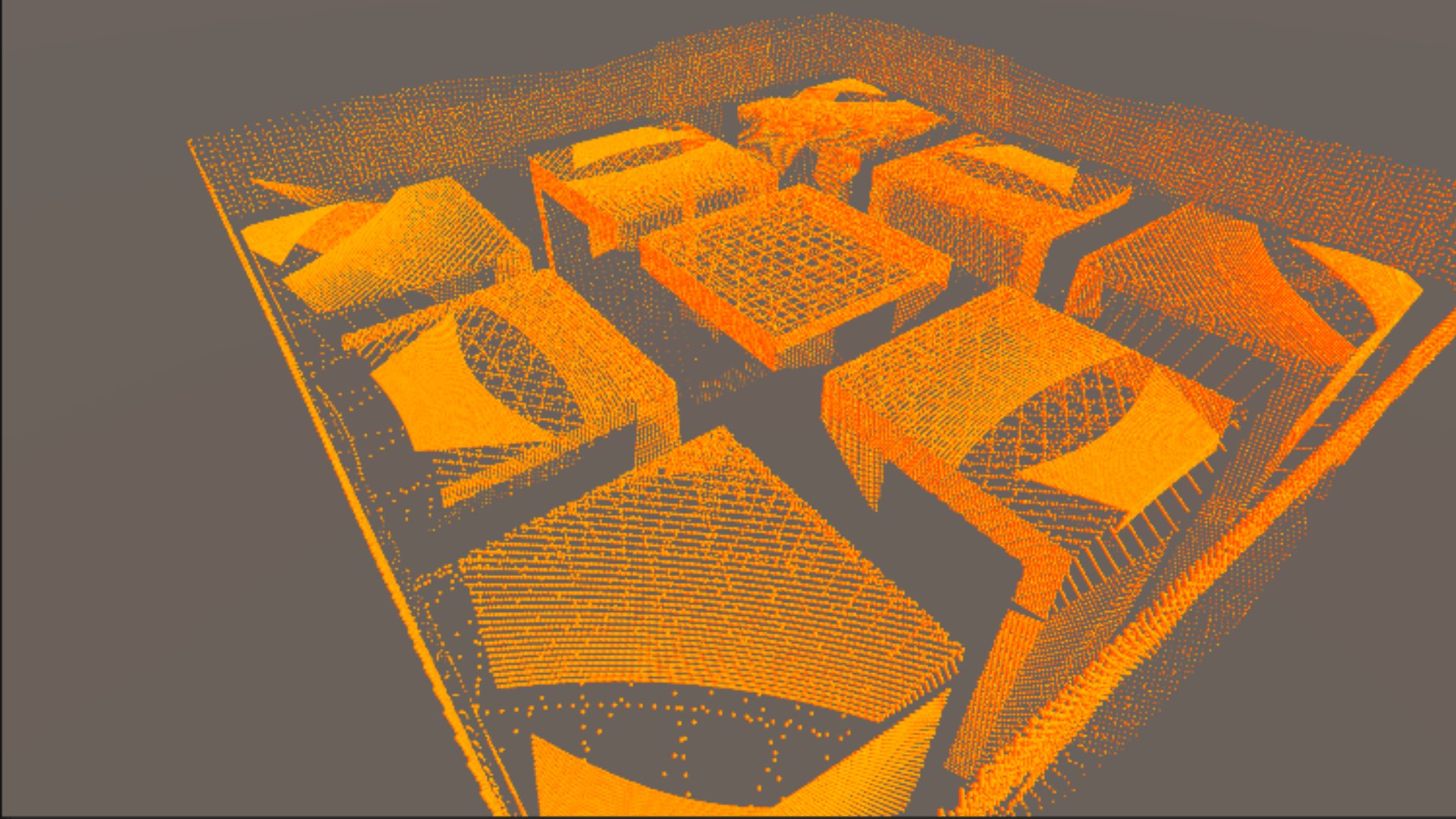

With the right software, 3D LiDAR solutions can solve these problems by scanning the surface of the target material thoroughly, creating an accurate lidar point cloud, and using the surface's spatial data to calculate the volume of the target material in real-time.

Precise 3D point cloud map of a recycling plant created with LiDAR solutions

Moreover, LiDAR's ability to work in low light and darkness gives customers peace of mind that their operations and storage can be monitored continuously and instantly, around the clock. LiDAR is unique compared to other optical reconstruction methods because it doesn't require ambient light.

By using a precise volume-measuring system as part of your inventory management, you can improve the accuracy of your inventory, improve delivery confirmation, ensure shipments arrive on time, and reduce the risk of stock shortages and overstocking.

Hardware and software can detect volume intelligently on a variety of surfaces and materials in the same recycling plant.

The following section will cover some use cases that Outsight's Augmented LiDAR Software solves.

Examples of volume measurement applications using LiDAR

Warehouse inventory volume calculation

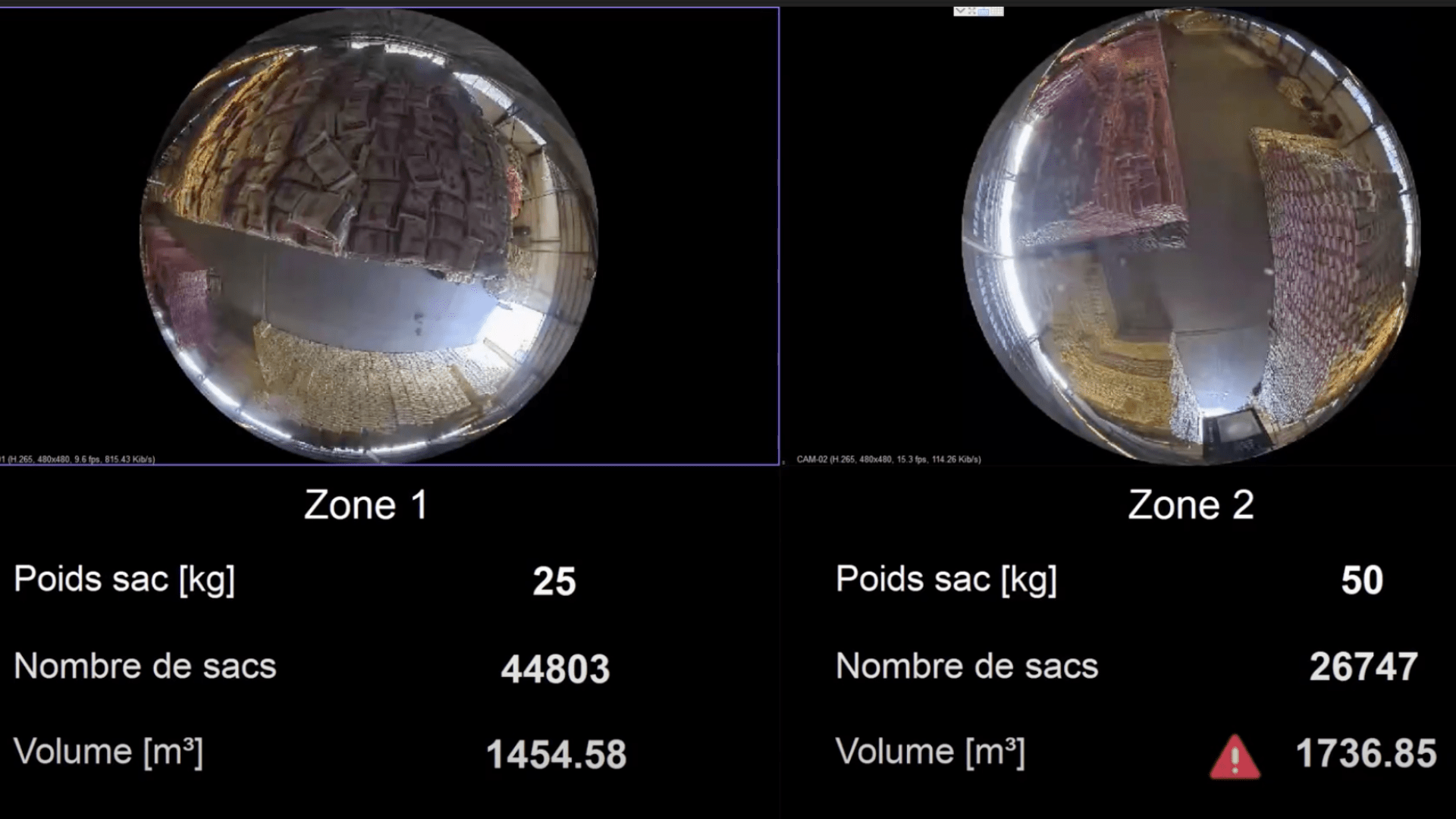

In this case, an Outsight client was having trouble monitoring the inventory of a vast warehouse, which contained several heaps of rice bags, and preventing product theft.

Due to their basic design, the previously deployed sensors could not provide comprehensive, real-time data for adequate level monitoring and inventory management.

Therefore, the client chose Outsight's Augmented LiDAR Software to calculate the volume of the inventory and the number of bags in each heap and identify people moving around the warehouse.

Outsight's Simulation tool optimized the solution by determining the appropriate amount, location, and kinds of LiDAR sensors required.

The next video shows the 3D point cloud of the warehouse with the inventory inside it, generated with Outsight's LiDAR technology and software.

LiDAR software' volume measurement feature allows this visualization

Finally, an alarm would be triggered if an abnormal and unexpected volume change occurred, and a video would be provided to verify the alarm.

Segmenting and measuring truckload volume

Paper mills and manufacturers worldwide face challenges in confirming the accuracy of their fiber material purchases. These difficulties are due to the limitations of weight control, which may not be sufficient to ensure the material's correct volume and water density.

For these clients, accurate volume measurement is crucial for verifying the purchase price and ensuring that internal processes, which depend on the material's water content, run smoothly.

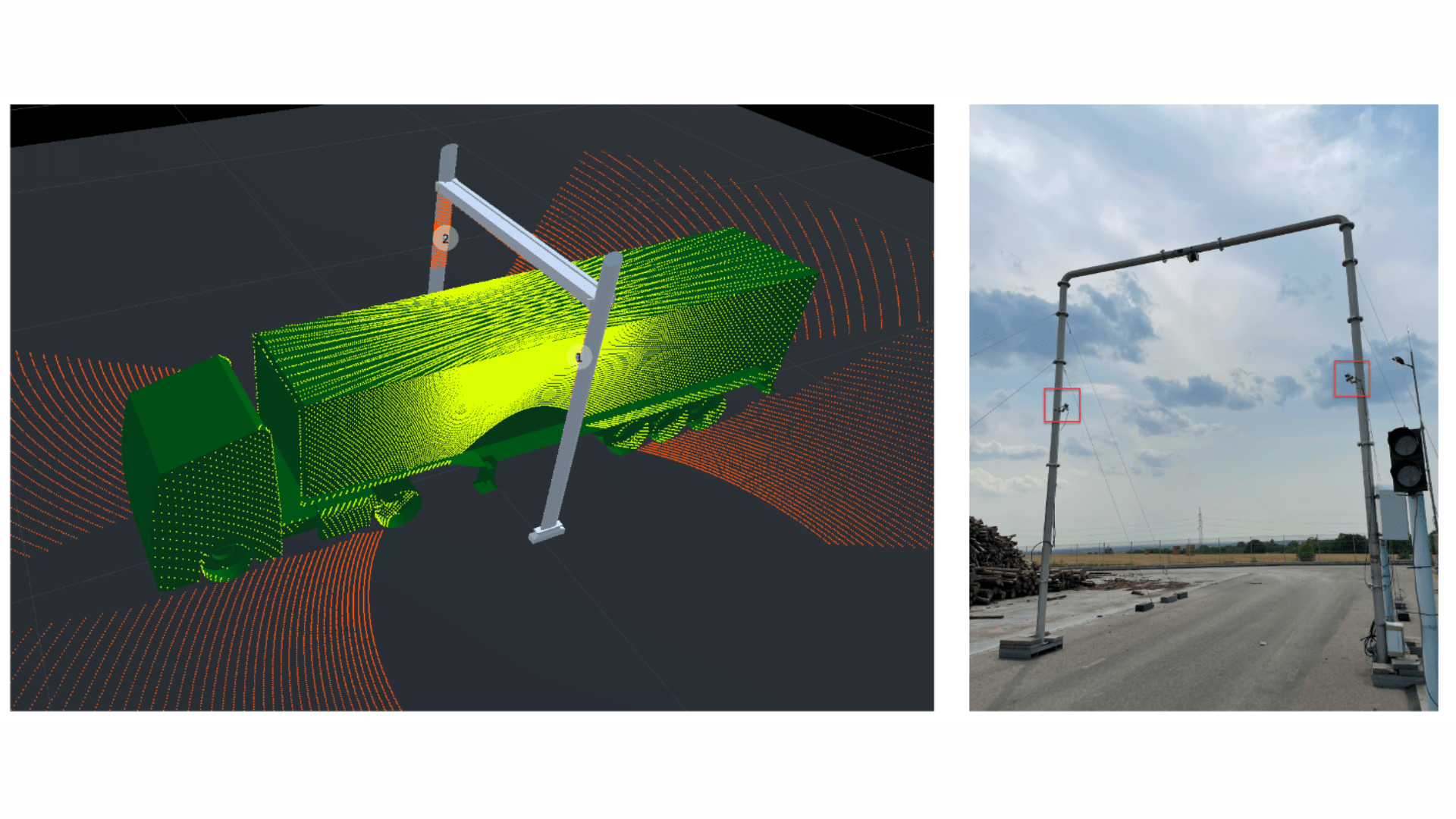

A leading pulp and paper industry research firm selected Outsight's Augmented LiDAR Software for a new 3D system solution to address this challenge.

This system, consisting of two LiDAR sensors mounted on a gantry, used Outsight's software to merge the LiDAR data and provide detailed information about the truck's load, including dimensions and volume.

This technology allows for rapid and automated measurement of the volume of large quantities of fiber material delivered by truck, providing the necessary information to guarantee that the lot is correct.

Outsight's volume measurement solution illustrated

Outsight's software plays a crucial role in solving the problem of accurately measuring the volume of moving objects. Its unique ability to fuse point clouds from two LiDARs and create 3D models allows for precise volume calculation.

The accompanying application enables users to easily extract actionable insights from the generated data, providing complete autonomy for segmenting a vehicle's load and calculating the volume of multiple trucks.

Finally, the 3D system achieves high accuracy despite using only two LiDARs, making it a reliable and efficient solution.

SLAM algorithm is used to generate a super-resolution scan

Conclusion

In the end, 3D LiDAR technology, when paired with the right software, is the most advanced and effective way to solve problems with measuring volume and make things run more smoothly.

Together, the hardware and software for LiDAR systems make up robust solutions businesses can use to improve their operations and logistics, gain a competitive edge, and grow over time.

To discover more about LiDAR software, download our whitepaper or contact a product specialist.