How LiDAR Is Changing Construction Site Safety

Gain an understanding of the role that 3D LiDAR technology plays in contributing to a significant increase in the level of safety on construction sites.

Construction sites are inherently dangerous places to work.

Every year, thousands of construction workers are injured as a result of hazardous working conditions. As an illustration, whereas only 6 percent of American workers are employed in the construction industry, this industry accounts for over 20 percent of worker fatalities nationwide1.

This difference highlights the need for ongoing efforts to increase workplace safety for people employed in the construction sector. Thankfully, this is where LiDAR technology comes in: saving lives thanks to capabilities that were not available before.

Read on to learn more about how LiDAR is changing construction site operations and safety .

Why is LiDAR data useful?

One of the greatest benefits of LiDAR is that it’s able to produce highly accurate, detailed 3D images of the surrounding environment in any lighting conditions.

From there, these images are then processed and stored as datasets that can be used in basically two different forms:

- In real-time: that is, the information is used instantaneously, for example, in order to raise an alert following a dangerous event;

- Aggregated over time: the information is used to get statistical measurements over time that deliver insight. For example, in order to understand in what places and when these kinds of events are happening.

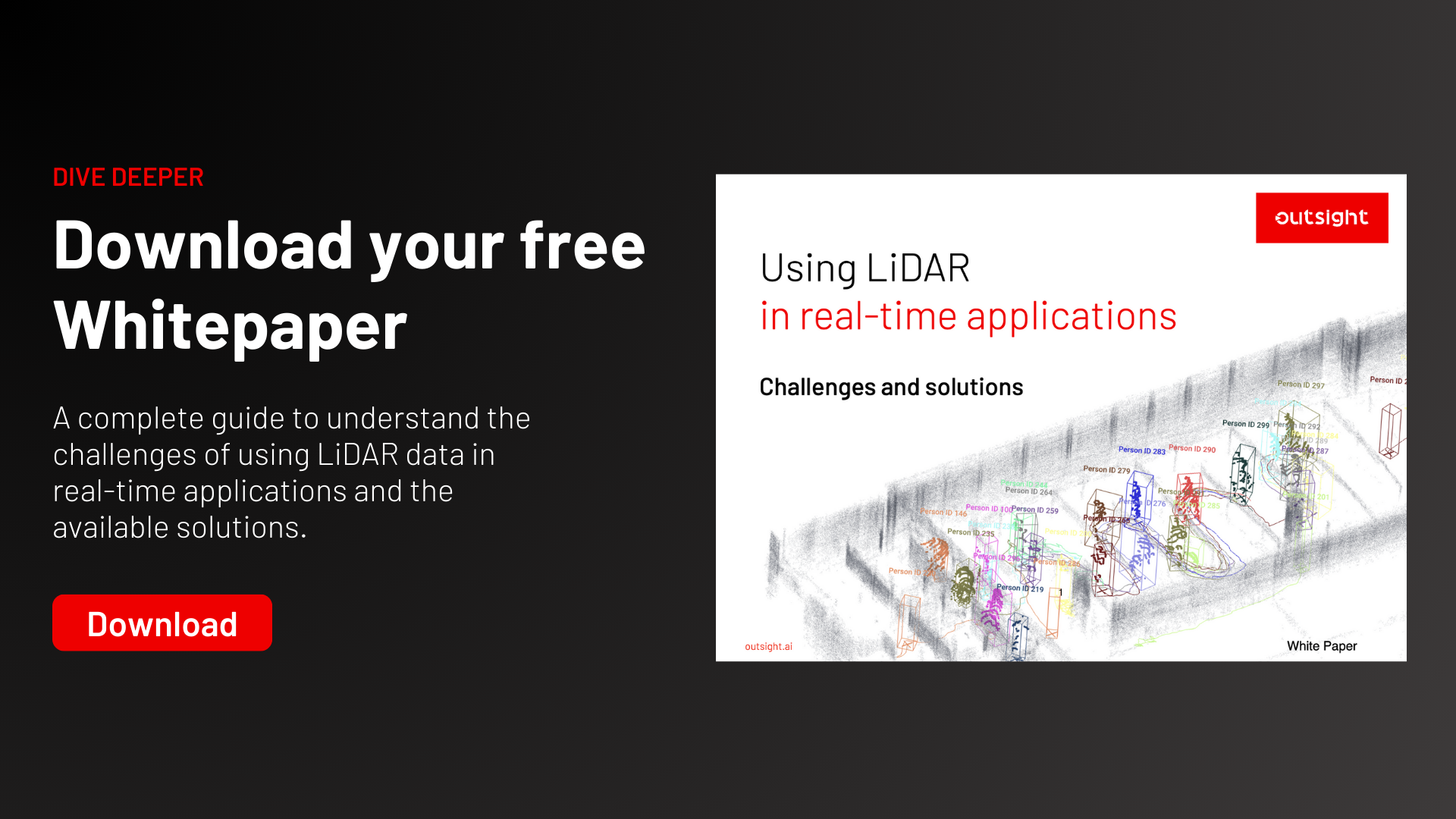

Outsight provides a LiDAR-agnostic software solution that makes it easy and fast to employ LiDAR in any application. To know more, don’t miss our latest article What's a 3D LiDAR Preprocessor detailing the key principles of the technology:

Safety Benefits of LiDAR in Construction

As we’ve already discussed, working on a construction site is inherently dangerous. Even if every worker on the job site follows all the safety protocols and best practices to the letter, there’s no way to completely eliminate all risk.

However, with the help of LiDAR, there are some pretty clear ways in which construction site safety can be improved and the consequences severely decreased.

Let’s take a look at four top benefits:

- Worker's safety through Object Detection

- Accurate Site Mapping

- Project simulations

- Quality control in construction

Workers’ safety using Object Detection

Another major benefit of LiDAR in the construction industry is the potential to reduce fatality rates among workers on the job site.

This is possible thanks to LiDAR ability to detect obstacles and hazards that humans might miss due to a lack of visual or auditory stimuli.

As a great example of a safety measure implementation, one of our clients is using the Outsight Augmented LiDAR Box to process data from a LiDAR sensor installed on a Crane, in order to detect dangerous situations and collisions with both machines and workers.

This application makes it possible to dynamically adapt the safety zones defined by the position of the block and the shape of the load because the collision could be caused by the load and not only the crane itself.

An alarm is triggered if a person enters the safety zone.

The same principle applies to LiDARs installed not only in infrastructure-based machines such as cranes but also in mobile heavy equipment.

Because the LiDAR sensor perceives the world in three dimensions, the typically rough terrain encountered in these situations does not cause false alarms.

Accurate Site Mapping

One of the most important benefits of LiDAR in construction is the development of accurate site maps and floor plans, and more recently, the creation of a Digital Twin.

Traditionally, this has been done using manual mapping and surveying tools, such as 2D LiDAR scanners and, more recently, photogrammetric technology. Both solutions, in reality, tend to be time-consuming and often create inconsistencies in the mapped data.

In contrast to that, a 3D LIDAR system is designed to generate several light beams to gather more comprehensive object data, as opposed to a 2D LIDAR system, which sends just one light beam towards a surface. Thus, switching to 3D LiDAR significantly reduces the time and effort required for site mapping as well as improves the quality of the data being collected.

For instance, using Outsight’s LiDAR preprocessing software, you can easily generate a point-cloud 3D map and obtain a precise vision of your site in a matter of minutes.

Project Simulations (or ‘Virtual Reality’ setups)

In this application, the 3D LiDAR is actually the starting point for simulating a construction project in its entirety.

Besides the modelling task, the 3D LiDAR can also capture how the dynamic component of the world changes, whether slowly—like when assessing a stockpile evolution over days—or quickly—like when transferring employees and machinery.

As a result, project managers can obtain a better picture of how the project will seem in practice during the development phase.

As an illustration, one of Outsight's clients utilised our simulation tool to create certain scenes and evaluate the effectiveness of 3D LiDAR systems in various settings, ensuring that all potentially dangerous scenarios would be addressed by their application.

Quality Control (QC) in Construction

Traditional paper-based QC is usually a labor intensive and expensive technique.

One such method uses vision-based approaches, where the major step is acquiring digital photographs on-site and connecting the images to the 3D CAD models.

After that, a QC check is done by comparing the site's digital photos to the CAD models to identify any discrepancies.

Now, these techniques are being replaced by 3D models, where 3D objects are identified with laser scans and superimposed with project 3D CAD models, using three matching reference points.

Conclusion

Construction sites are inherently dangerous places, but with the help of LiDAR technology, it’s possible to reduce the risk of accidents and make sure project timelines are met.

From people’s safety, automated mapping solutions to 3D reconstruction and modelling and risk management, there are many ways in which LiDAR is revolutionising construction site safety.

Our mission at Outsight is to build the easiest and most efficient way to use 3D LiDAR data in any application.

With the use of our real-time pre-processing software, it has never been simpler to develop advanced 3D-based solutions for the Construction industry.

Sources

- U.S. Bureau of Labor Statistics