The 10 Reasons to Use a 3D Software Processor

Dive into this article to grasp the essential reasons for utilizing a LiDAR software processing solution, empowering you to leverage the unique value of 3D Data.

A 3D LiDAR Software Processor turns RAW data into actionable information

Running in real-time, LiDAR processing software takes raw 3D data as an input and instantly converts it to accessible, actionable insight.

As any piece of technology, instead of buying it, in theory you could just build it yourself.

So what are the main reasons to use a Software Processing Solution?

3D processing software allows you to use 3D LiDAR data in real- time by employing a comprehensive set of features and a seamless plug-and-play integration.

You can start leveraging the unique value of 3D data instantantly or jumpstart building your specific solution from day one.

As the leader in real-time LiDAR Software Outsight pushes the limits of this concept even further: in the video below we show how to get from first plugging your LiDAR to Object Tracking and Zones of Interest definition in 90 seconds, without installing any framework, library or software in your computer.

From Zero to Tracking Objects in 90 seconds

In a nutshell, a 3D LidAR Software processing solution allows you to focus on what's important - insight instead of raw data.

Pure LiDAR software players such as Outsight have many years of experience implementing highly efficient professional LiDAR software in a range of environments for the most demanding applications.

Overview of LiDAR applications with Outsight's software

Most of the applications listed in this article comes from our own many-years experience:

Leveraging this experience ensures that you avoid the many pitfalls encountered by those building internal solutions.

Employing lidar processing software allows you to benefit from the work of a team of experts at a fraction of the cost of in-house or outsourced engineering.

Especially when accounting not only for the development time but also the maintenance cost.

While making a prototype, demo or R&D-level software can be done relatively quick, building a professional solution is much harder, longer and expensive.

Using a LiDAR processing software that is already compatible with most if not all of the available LiDARs allows you to use the most appropriate sensor(s) for your application and environment.

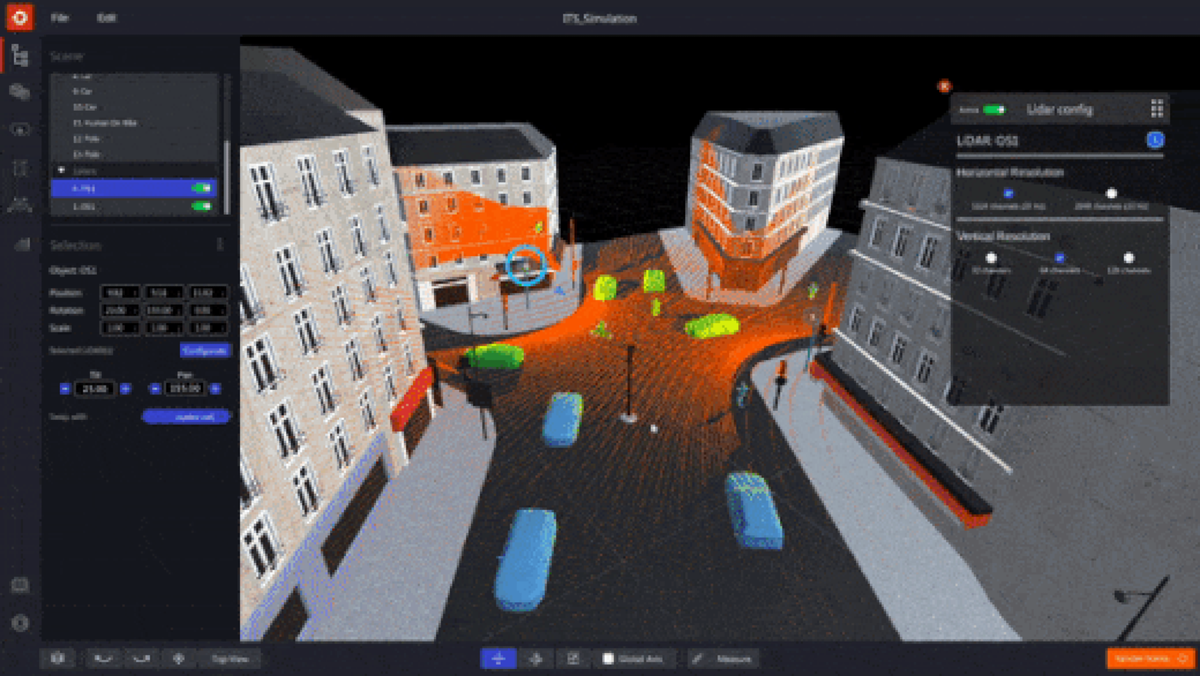

In order to allow our customers and partners to choose the right LiDAR or combination of LiDAR manufacturers, we have developed a multi-vendor Simulation Tool:

For example, when deploying in a first site, one of our customers in the People Monitoring space used a LiDAR model from a leading manufacturer.

When we started deploying the second site, the customer decided that combining a second and third manufacturer's products, was the best solution. Two sites, three manufacturers.

Why? Because the physical characteristics of the sites differed, with some having low ceilings and narrow aisles and others having large open spaces, different sensor capabilities were more or less appropriate (FoV, range...).

The second reason was the time difference between the two sites' deployment, that allowed newer solutions to emerge: the former leaders of LiDAR years ago are not necessarily those of today and tomorrow.

If you are a systems integrator or technology company, LiDAR Processing Software doesn’t replace the value of your application-specific solution, which allows you to create unique products that are tailored to your specific needs and keep the associated full IP rights and value of what you built.

For example, take a look at this Cookbook that we published, allowing any developer to build many types of different applications, in this case for Intelligent Transportation Systems:

Good 3D processing software comes with ready-to-use application examples that allows you to benefit from similar issues that have been solved in other industries and contexts.

The Outsight team has more than 18 years' experience building real-time LiDAR solutions in many different markets and situations with dozens of different customers.

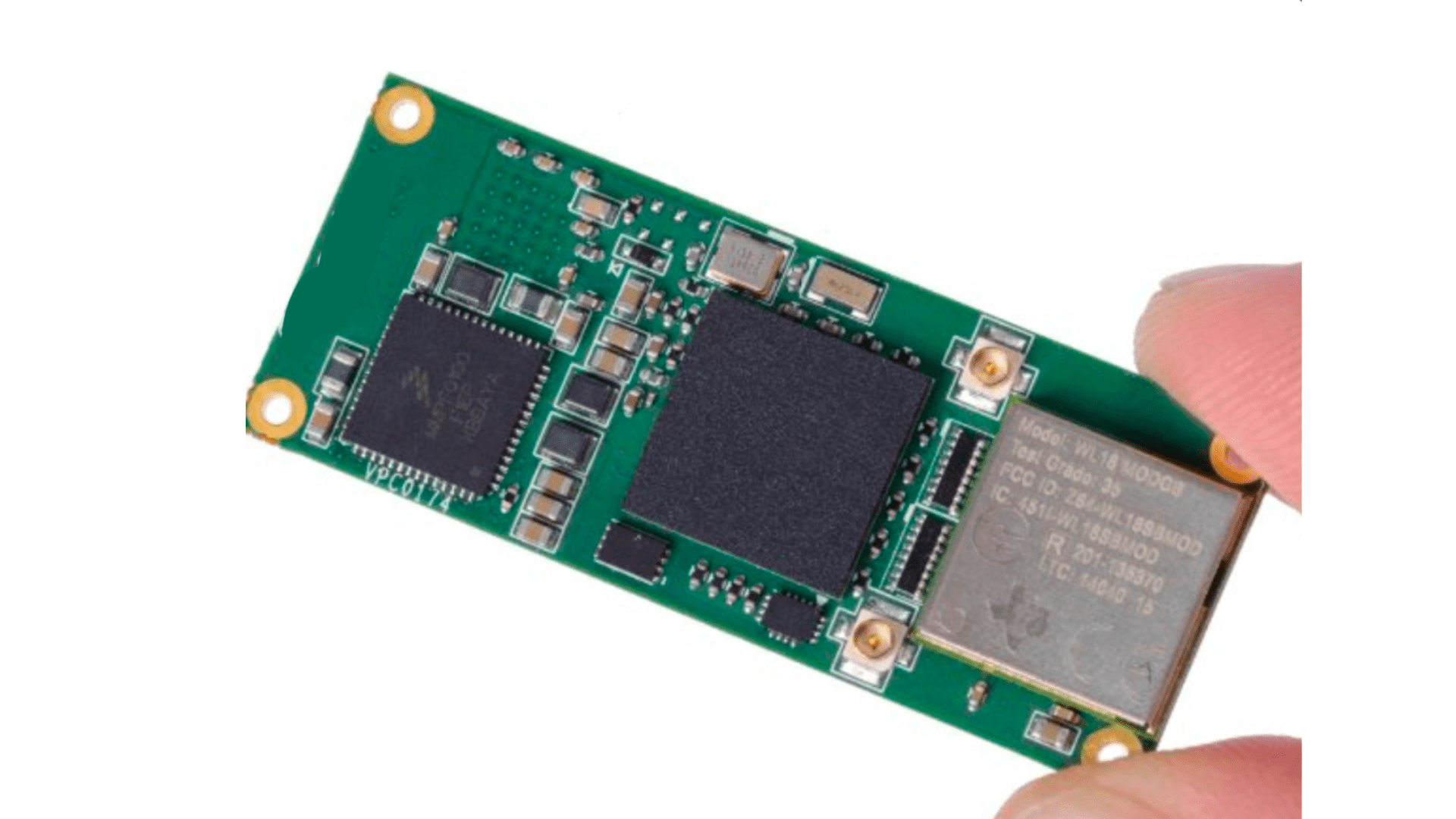

When using the right LiDAR processing software solution, Edge computing requirements must be as low as an ARM CPU, which drastically reduces the application’s power and heat dissipation constraints.

This will become even more difficult as LiDAR performance is expected to improve by tens of millions of points per second (pps) in the near future.

Incidentally, our distinct Edge AI processing capabilities were a pivotal factor in securing us the title of 'Edge AI Vision Software Product of the Year':

A combination of various LiDAR sensors, including products from different manufacturers, is often needed to produce the best results: doing so without processing software is incredibly challenging and can lead to major project setbacks.

Combining these different manufacturers and models, for example, necessitates dealing with synchronisations, calibration, networking and scanning pattern differences that are not easy to resolve.

You can learn more about it in this article:

Building state-of-the-art 3D LiDAR real-time software is a full-time job for specialists.

It requires a multi-disciplinary team that is hard to build in-house (Localization, Perception, Tracking, Embedded software, UI/UX, QA...)

To achieve state-of-the-art performance and scalable solutions, a critical mass of world-class talent is required, which is difficult to achieve if 3D processing is not your primary activity.

Being able to seamlessly use multiple hardware sources, both for processing and sensing, is becoming increasingly important in today's uncertain geopolitical situation and supply chain constraints.

Professional LiDAR processing software abstracts the hardware, both from the sensing and the computing aspects, reducing risks and allowing for easy hardware switching.

A 3D LiDAR processing solution's development lifecycle necessitates a variety of advanced tools, ranging from 3D simulation to data recording, annotation, and replay, not to mention quality assurance processes and tools.

A professional team providing pre-processing solutions allows all of their customers to benefit from the substantial investment required to build and maintain this pipeline.

Want to know more? Contact a Product Specialist or take a look at our latest white paper: